Cash in on Reverse Logistics

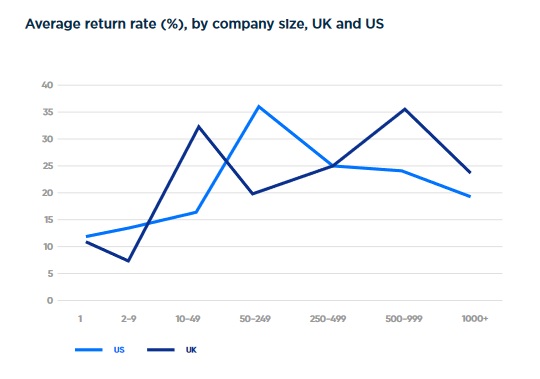

Reverse logistics has long been the problem child of supply chain management. Increasingly that child has been in need of some serious help. This is due to two factors. The way in which the internet has transformed how we shop, and the short lifecycle of consumer goods. Although most consumers still like to shop in high street stores to find the products they like, at least 8% of sales are now from consumers just clicking on a picture to buy a product, comfortable in the knowledge that they can return it if necessary. In most countries, consumers have a legal right to return goods purchased on the internet. Many retailers now even offer free ‘try-before-you-buy’ returns, but the processes for managing those returns, known as reverse logistics, are far more fragile, costly, and susceptible to issues than the generally well-controlled forward logistics processes. Although return rates vary widely across different verticals, the average return rate has been calculated to be around 17 to 18%.

Source: Brightpearl

Reverse logistics faces complex issues due to the ad hoc way in which consumers return items and vulnerabilities in the returns processes. Because reverse logistics is not seen as a revenue-generating process, it sometimes doesn’t get the attention it needs, but recently it’s been getting more widely recognized as having a key role in the company’s profitability. Having efficient processes for collecting, re-selling or recycling used items can bring in additional revenue and improve a company’s bottom line. There are other important reasons for giving more attention to reverse logistics. Consumers are now judging companies on their green credentials, and consumers are aware that many electronic devices contain some highly toxic chemicals. Providing a channel through which old devices can be traded in and reliably recycled is a positive selling point. The efficiency of the returns process also has a significant impact on customers impression of a business.

Although the ‘returns revolution’ impacts all retail lines of business, high-value consumer electronics are especially prone to issues in the returns process. Huge volumes of handsets, set-top boxes, routers, even TV’s and laptops, are now being returned through a multitude of channels for a variety of reasons. Warehouses may receive thousands of such goods per week. Most of those devices may still be working and able to be resold, but tracking such devices back from customers, assessing their viability for resale, refurbishing, repackaging, and then re-distributing them, is a substantial challenge.

Typical return channels would be to send a device by courier, return it to a shop, or a technician may return the goods. Whatever the channel is, devices will often arrive without a clear indication of which customer account they relate to. Returns to stores are particularly problematic with agents failing to scan in barcodes or register returns correctly. In-store systems may not be able to record IMEI, IMSI and/or serial numbers, and there is no motivation for staff to label returned devices accurately.

With so many moving parts it’s no surprise that many devices become stranded or lost along the way, and customers getting charged incorrectly. Operators have been known to write off more than $5+ million in lost devices per month.

One solution is to implement automated controls that provide monitoring across all systems in both forward and reverse logistics, thus assuring that devices can be monitored from the initial order in CRM, in and out of warehouses, with couriers, shipping, refurbishment partners, finance companies and activation status in network service provisioning. With monitoring systems in place that can even detect the physical location where devices are installed, it’s possible to validate inventory, bill customers and partners accurately, prevent fraud, recover maximum value from returned devices and understand why devices are getting returned.

Subex provides ROC Device Assurance solutions to operators around the globe, helping to track down missing devices, reconcile and correct billing, CRM, provisioning, distribution and inventory systems with world leading discovery and reconciliation capabilities.

Want to know how our Asset & Inventory Assurance solution can help your organization

Mark Jenkins has worked in the IT industry for over 15 years as a BI and Analytics consultant, and more recently as ROC Product Manager for Subex Ltd. He has designed and deployed solutions for global companies in many sectors including Insurance, utilities and telecommunications. Mark holds a BSc Hons in Computer Science from Manchester University (UK).

Request a demo